Emulsions — mixtures of two immiscible fluids where one is dispersed in the other in the form of droplets — are ubiquitous in both industrial and consumer products, from cosmetics and coatings to food applications such as mayonnaise. The stability and behavior of these emulsions under mechanical stress is a critical factor in formulation, processing, and quality control.

Mayonnaise -in particular- is a complex oil-in-water emulsion that must maintain a delicate balance between stability and texture, even when subjected to strong shear flows during mixing, transport, or usage. Under shear, droplets may deform, coalesce, or break up —phenomena that directly affect viscosity, appearance, and mouthfeel.

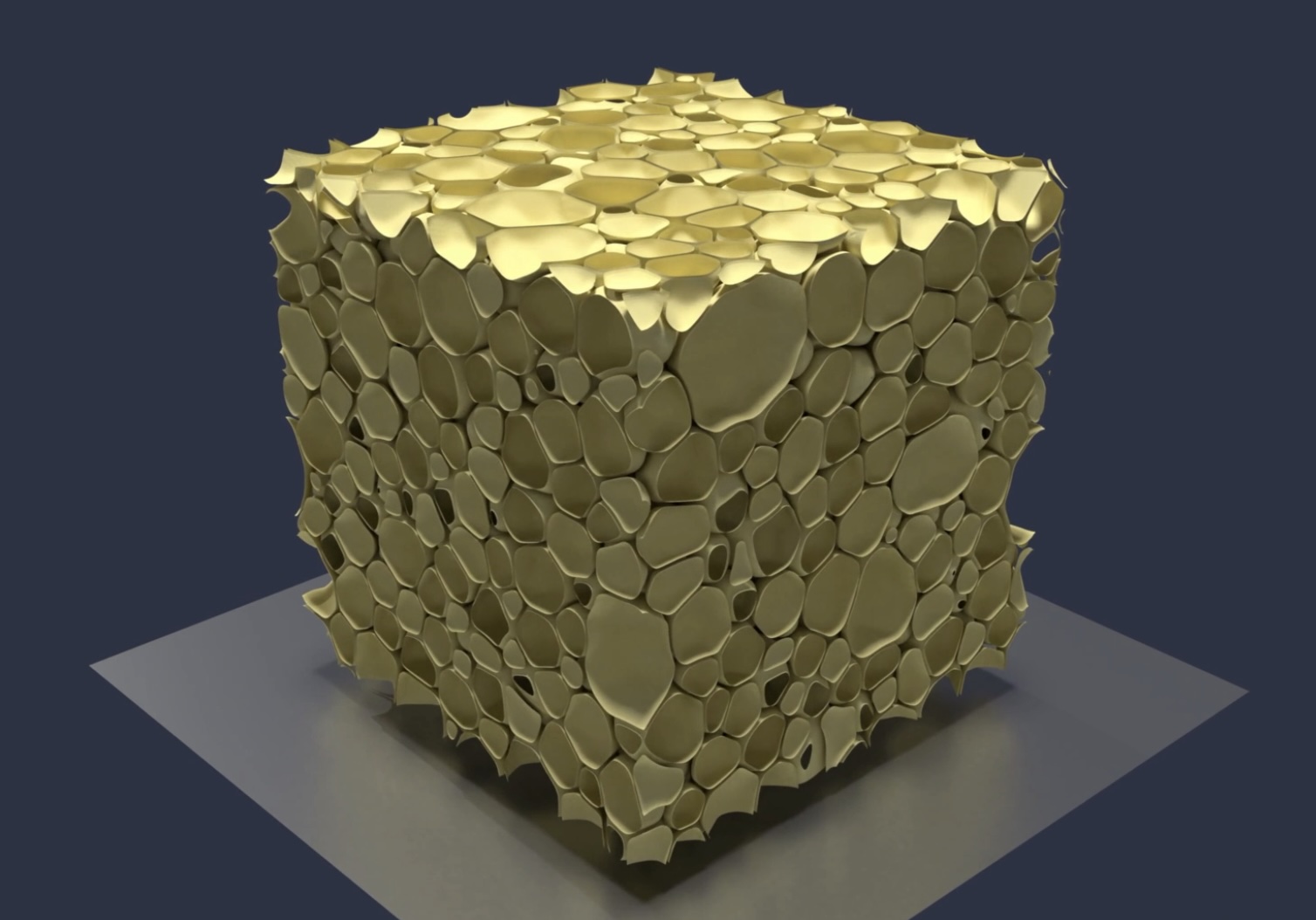

At FLOW Matters Consultancy, we apply high-fidelity lattice Boltzmann simulations to investigate the physics of emulsions at microscale. The model employed have been developed and validate in many previous studies [1], [2], [3], [4]. Here, we employ the Shan-Chen pseudopotential model [5] coupled with a double-belt algorithm [6], we initialize a Couette-like shear setup to replicate the behavior of a mayonnaise-like emulsion between two counter-sliding walls. The model can capture the complex interfacial dynamics, including droplet deformation, shear thinning behavior, coalescence and breakup events. Our approach allows us to directly link the microscopic physics to the macroscopic rheology, providing valuable insights for industrial partners working on emulsion-based formulations. With this tool, we can explore how formulation parameters (e.g., droplet size distribution, phase volume ratios, phase viscosity properties) and processing conditions (shear rate, mixing protocol) influence flow behavior and product composition under realistic processing conditions.

In the video, one can clearly observe how the dispersed phase evolves under shear, with droplets elongating, interacting, and occasionally merging —an accurate and predictive simulation of the internal microscopic mechanics a real mayonnaise emulsion under controlled mixing.

This project exemplifies our mission: bringing advanced fluid dynamics from applied research to industrial practice. Whether you’re optimizing a new product or troubleshooting a process line, FLOW Matters is ready to bring simulation-driven innovation to your workflow.

[1] I. Girotto, K. Datadien, G. Di Staso, S. Schifano, R. Benzi, and F. Toschi, “The chaotic life of mayonnaise,” in English. In:(Nov. 2019). 72nd Annual Meeting of the APS Division of Fluid Dynamics (DFD 2019), 2019.

[2] I. Girotto, R. Benzi, G. Di Staso, A. Scagliarini, S. F. Schifano, and F. Toschi, “Build up of yield stress fluids via chaotic emulsification,” J. Turbul., vol. 23, no. 6, pp. 265–275, 2022.

[3] I. Girotto, A. Scagliarini, R. Benzi, and F. Toschi, “Lagrangian statistics of concentrated emulsions,” J. Fluid Mech., vol. 986, p. A33, 2024.

[4] L. Yi, I. Girotto, F. Toschi, and C. Sun, “Divergence of Critical Fluctuations on Approaching Catastrophic Phase Inversion in Turbulent Emulsions,” Phys. Rev. Lett., vol. 133, no. 13, p. 134001, Sep. 2024, doi: 10.1103/PhysRevLett.133.134001.

[5] X. Shan and H. Chen, “Lattice Boltzmann model for simulating flows with multiple phases and components,” Phys. Rev. E, vol. 47, no. 3, p. 1815, 1993.

[6] M. Sbragaglia, R. Benzi, L. Biferale, S. Succi, K. Sugiyama, and F. Toschi, “Generalized lattice Boltzmann method with multirange pseudopotential,” Phys. Rev. E, vol. 75, no. 2, p. 026702, Feb. 2007, doi: 10.1103/PhysRevE.75.026702.

Leave a Reply